Tailored to Your Needs

Danzer produces large volumes of standard veneers made from the world’s major hardwood species. Our production capabilities allow us to supply many different types of customers with exactly what they need when they need it. Proprietary best-in class VS4000 slicers and experienced teams enable production of the highest quality products, and our customer-specific programs ensure delivery of consistent color, grade and dimension veneer. With Danzer, customers benefit from a higher manufacturing yield, reduced need for working capital, and the confidence that comes from working with a partner committed to sustainable practices.

What We Offer

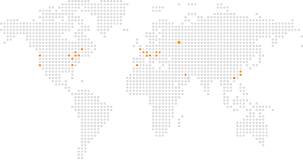

Danzer offers decorative hardwood veneers from all major North American, European and African species for use in furniture, interiors, mobility applications and more.

We produce large volumes of standard veneers for industrial users in different types of cuts, thickness and grades. Major standard veneer species by region of origin are:

North America

|

|

|

Europe

|

|

|

Africa

|

|

|

We carry more than 200 species from all over the world. In addition to standard veneer, we offer rare and exotic veneers and technical veneers. We also offer veneers featuring a wide range of special treatments including vintage, fumed or smoked looks.

The majority of our standard veneers come clipped and bundled. Our clipped veneer can be acquired in random widths and random lengths. For customers in North America we also carry a competitive range of unclipped veneers.

Our standard veneer thicknesses are:

- Depending on the species: around 0.5 mm

- Other thicknesses such as 0.9 mm or 1.5 mm are also on stock

- We slice different thicknesses precisely by order (thinner or thicker than standard)

- We also have an extensive range of sliced wood in 2.5 mm, 3.0 mm and even 4.0 mm (see flooring lamellas)

Why Buy from Danzer?

Superior quality

The consistent quality of our products is driven by experience and technology: Danzer has developed its own proprietary, best-in-class slicer technology. That combined with the systematic quality-control steps we take throughout the production process enable us to meet or exceed exacting standards.

Comprehensive product range

Danzer offers the largest volumes and broadest product range in the veneer industry, ensuring extensive choice and reliable supply. One-stop shopping makes procurement easier for our customers, and customer-specific programs ensure delivery of veneer tailored exactly to their needs.

Exceptional customer service

At Danzer, we’re attuned to our customers’ needs. Our competent sales staff responds to requests quickly. We work closely with customers to develop tailored programs that assure they receive the right product at the right time.

A responsible partner

Raw material for Danzer veneer is sourced exclusively from sustainably managed forests. We are chain-of-custody certified and continuously invest in audits to assure adherence. Most veneers are available in PEFC™, FSC® Certified (FSC 100%, FSC Mix) or Controlled wood.

Exceptional customer service

At Danzer, we’re attuned to our customers’ needs. Our competent sales staff responds to requests quickly. We work closely with customers to develop tailored programs that assure they receive the right product at the right time.

A responsible partner

Raw material for Danzer veneer is sourced exclusively from sustainably managed forests. We are chain-of-custody certified and continuously invest in audits to assure adherence. Most veneers are available in PEFC™, FSC® Certified (FSC 100%, FSC Mix) or Controlled wood.

How Do You Benefit?

Satisfied customers

Using high-quality Danzer veneers makes manufacturing easier. Our high levels of availability enable our customers to deliver final product to their customers on-time, and our high degree of consistency reduces likelihood of claims.

Lower cost

Danzer’s customer-specific product offerings improve yield and increase operational efficiency. We provide the product data needed to easily integrate into the production workflow to maximize productivity. And our ability to meet customers’ needs, in volume, price, and delivery time, allow them to maintain lower inventory levels and reduce working capital needed.

Time to focus on core business

Danzer’s reliability gives customers the time to focus on their core business rather than worry about veneer procurement. Our customers take comfort in the knowledge that our products are sourced sustainably and legally.